Our Production Products

Dodge Challenger Shaker

Dodge® wanted to bring back the nostalgic Shaker Induction from the 1970 Challenger to pay homage to the muscle cars of years past in a serialized limited run known as a "Buzz" model in 2014. This project severely challenged NAA with the top half protruding through the hood, a Class A exterior body component while the lower half needed to be a performance air induction system. NAA stepped up, while others were reluctant to venture into this cross-functional realm and developed the 2014 Shaker for the 5.7L.

It was so well executed by NAA and desired by the performance enthusiast that it became a vehicle option on the Challenger 5.7L and NAA developed provisions for the 6.4L as well and both models will run through to the retirement of the combustion engine Challenger in 2023.

As the program progressed it arose to be the highest grossing Mopar® product in Mopar’s 86 yr. history.

This program incorporated a labor-intensive low-volume production program featuring a multitude of manufacturing disciplines: Sheet Molding Composite (SMC), Injection Molding, Over Molding, Insert Molding, Laser Cutting, Steel Forming, High Temp Outgassing, CNC Machining, Robotic Machining, Exterior Prime / Paint, Convection Baking, Hand Sanding, Custom Material Handling, Vision System, DC Torque Drivers and Certified IATF 16949 Assembly Processes.

This system is completely manufactured at our two facilities in Auburn Hills, MI. with 100% of all components and tooling built in the US. This year NAA will surpass manufacturing 50,000 Shaker assemblies since inception with unprecedented stellar quality – to date, NAA has not had a single returned Shaker assembly for any reason from Dodge

Dodge Commerical Featuring Shaker

on Gas Monkey Garage ®

This program incorporated a labor-intensive low-volume production program featuring a multitude of manufacturing disciplines: Sheet Molding Composite (SMC), Injection Molding, Over Molding, Insert Molding, Laser Cutting, Steel Forming, High Temp Outgassing, CNC Machining, Robotic Machining, Exterior Prime / Paint, Convection Baking, Hand Sanding, Custom Material Handling, Vision System, DC Torque Drivers and Certified IATF 16949 Assembly Processes.

This system is completely manufactured at our two facilities in Auburn Hills, MI. with 100% of all components and tooling built in the US. This year NAA will surpass manufacturing 50,000 Shaker assemblies since inception with unprecedented stellar quality – to date, NAA has not had a single returned Shaker assembly for any reason from Dodge

Dodge Commerical Featuring Shaker

on Gas Monkey Garage ®

Supercharger LS2

The LS2 Supercharger was featured on performace models under the Chevy and Cadillac brands. Beginning in 2006 the production process involved bringing in products from five major manufactures.

Manufacturing process includes an automated line for leak check, part presence and continuity checks to all electronic components. Assembly stations feed the line and feature air assisted gyroscopics and build process led

Expanded ls2 information here. additional product information and background

Ram Airflow

With the newly styled DT Ram 1500 series light duty truck, Dodge wanted to offer a high performance “Cold Air” intake. Mopar® approached NAA with a concept that was not your typical air induction system, they requested that it span the entire engine bay from the cowl to the grill.

NAA accepted this almost insurmountable challenge and brought to market this first of its kind Cold Air Intake with several proprietary styling enhancements. NAA did extensive development along with Mopar on this unconventional Cold Air System and NAA was responsible for the unique design, manufacturing, validation and procurement to bring this system to market.

The kit was so well received as an aftermarket performance kit that it was implemented on the production Ram GT version of the 1500 series truck with 5.7L. Styling was a priority and NAA stepped up with proprietary extremely unique insert molded stainless steel trim and cosmetic Santoprene® convolutes and developed and incorporated an injection molded new Long Glass Nylon material to allow the system to span the engine bay. All molding is done in house by North American Mold, a division of NAA. To continue to enhance styling, NAA also added an argent silver hot stamped “RAM AIRFLOW”. NAA is currently producing volumes of 1200/month.

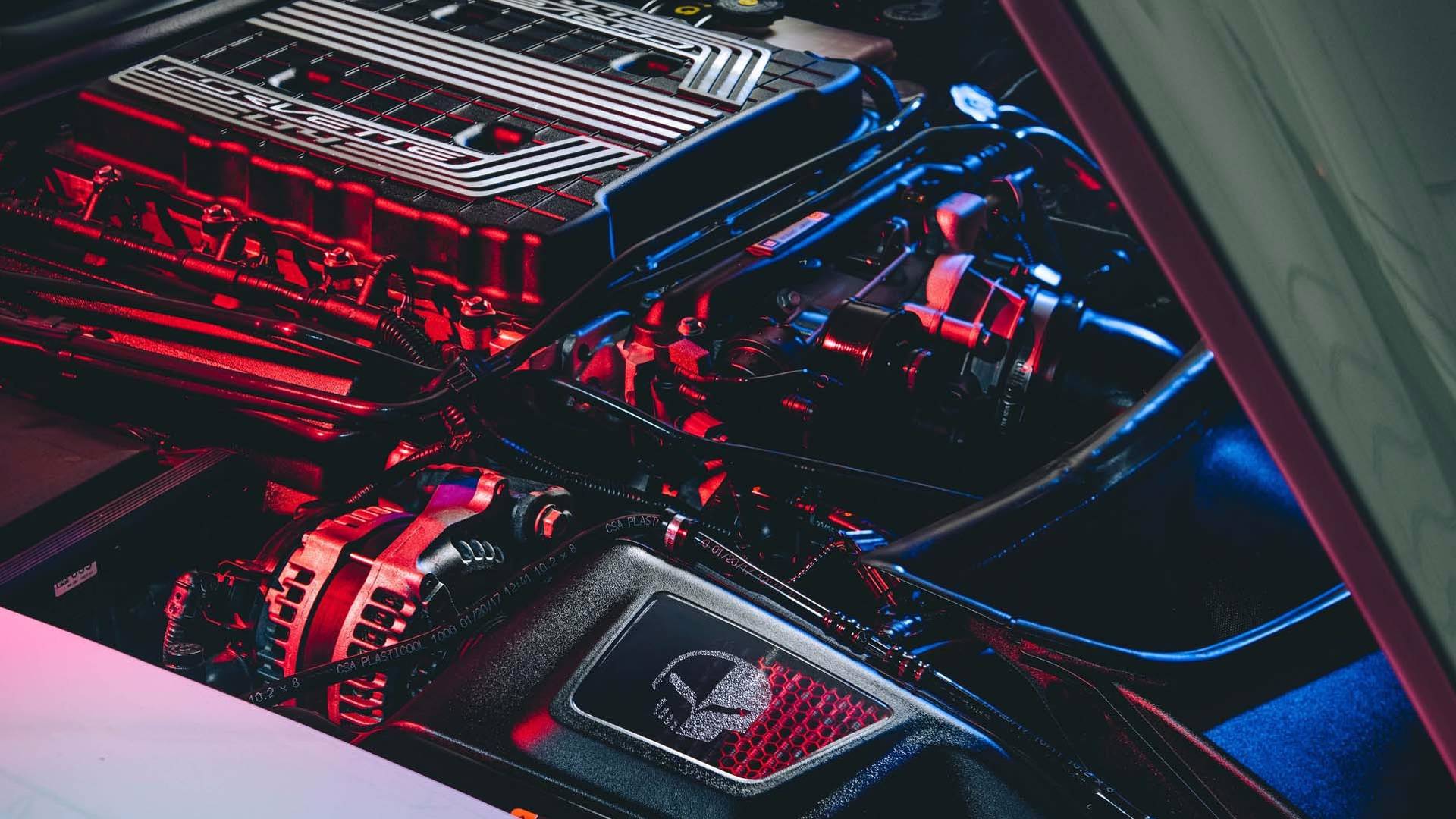

C7 Corvette Cold Air Induction

The C7 Corvette Induction System was NAA's first venture with the GM Performance group. NAA supplied an initial concept of a clear windowed with the Corvette badge molded into the center. The concept later evolved into a captured window with engraved logo.

Utilizing CFD analysis to optimize airflow and restriction and utilzing and a new filtration media NAA was able to exceed performace expectations and increase the C7's horsepower with a simple Airbox and Filter change while adding beautiful aestetics to the engine bay

Performace and Beauty were the main goals of the program, NAA was able to deliver on the goals by utilizing

new molding materials and molding methods as well bring new filtration media to the automotive market.

These materials and media quickly became stardard to NAA's product development futher pushing the envelope for what

can be achieved while exceeding OEM critera and standards

- NAA guaranteed a 10HP gain upfront to GM Engineers if NAA was allowed to completely re-design the GM OEM system

- NAA designed a new system that exceeded all GM expectationswith 17.1 HP

- 17.1HP is the highest power gain thru a CAI in GM history

- Custom performance filter and endless development to meet GM strenuous air flow “noise”

- Zero product returns

- First time NAA has sent directly to dealers (plug for a new potential OEM business)

- First to use translucent nylon on a window and proprietary insert molding

new molding materials and molding methods as well bring new filtration media to the automotive market.

These materials and media quickly became stardard to NAA's product development futher pushing the envelope for what

can be achieved while exceeding OEM critera and standards

- NAA guaranteed a 10HP gain upfront to GM Engineers if NAA was allowed to completely re-design the GM OEM system

- NAA designed a new system that exceeded all GM expectationswith 17.1 HP

- 17.1HP is the highest power gain thru a CAI in GM history

- Custom performance filter and endless development to meet GM strenuous air flow “noise”

- Zero product returns

- First time NAA has sent directly to dealers (plug for a new potential OEM business)

- First to use translucent nylon on a window and proprietary insert molding

Challenger T/A 2017+

With the success of the Shaker Challenger, Dodge continued with the nostalgia and approached NAA to design and develop the 2015 Challenger T/A paying homage to the 1970 SCCA Trans Am series race cars and limited production Challenger T/A and AAR Cuda.

NAA developed a performance air induction system with a hood mounted duct that provided a robust integrated sealing system to block hot air for entering the cold air stream offered by their hood mounted scoop.

This marks another FCA program that was slated for 3 yrs. and NAA will produce these systems until the vehicle is retired at the end of 2023

Mopar T/A Hood Venting System & V2

Mopar began offering a collector car package, a retro-styled T/A hood reminiscent of the 1970 Challenger T/A paying homage to the 1970 SCCA Trans Am series race cars.

NAA yet again was contracted to design a hood “venting” system that provided functional cold air intake to the engine. NAA still supplies this system that is manufactured in its two facilities in Auburn Hills, MI.

The cold air intake was updated for the Challenger, Charger and 300C. That created a problem for those who wanted to install the Mopar T/A style hood that would be functional.

NAA took elements of the 2010 version hood venting system and adapted them to the cold air intake. NAA creatively modified tooling that was a cost-effective solution that satisfied customer demand.